Flow Chemistry Reactor Technology is a vital component of Raleigh Molecular’s wide-ranging capabilities in custom chemical synthesis and process development. This innovative technology offers numerous advantages such as enhanced scalability, flexibility, and precise process control, contributing to improved efficiency and quality in our operations.

Flow Chemistry involves producing compounds through a continuous process utilizing automated pumps and specialized reactors. In this method, reactants flow as solutions within these reactors, and mixing occurs rapidly, taking only a fraction of a second compared to the longer time frames in traditional batch processes. The reaction is considered complete as the solutions exit the system. Since only a portion of the total material used in API and custom synthesis reacts at any given moment, the reactor volume is minimized, contributing to efficiency and resource conservation.

In a small flow reactor, the high surface area to volume ratio enables almost instantaneous control over reaction temperatures, leading to potentially cleaner products and enhanced reaction safety. Flow Chemistry also reduces scale-up challenges by ensuring consistent control of mixing and heat transfer throughout the reaction, even at larger scales up to a tonne. Additionally, Flow Chemistry allows for faster changeovers between different custom synthesis projects, enhancing overall operational efficiency.

Flow chemistry is often preferred over batch synthesis when it is expected to yield better results in terms of higher yields, quicker reactions, or safer operations. Additionally, it is chosen to explore novel or exotic synthesis routes that would be challenging or impractical using traditional batch technology.

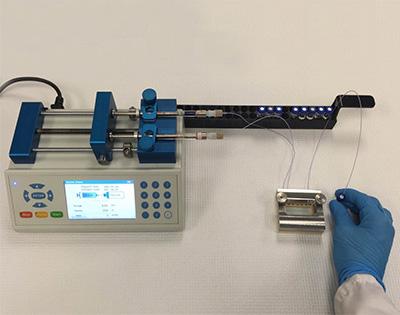

Dalton typically conducts initial investigations and proof of concept for Custom Chemical Synthesis on the milligram scale using a Chemtrix micro-reactor. A comprehensive experimental program, requiring minimal material, is employed to assess reaction kinetics and the impact of various operating conditions, usually completed within 1-3 days. When the production of more than a few milligrams of product is required, the process is scaled up using in-house flow reactors. Due to the nature of Flow Chemistry, troubleshooting is minimal. Overall, Flow Chemistry enables us to offer clients a more cost-effective, efficient, and safer approach to API process development and custom synthesis.

©2014-2024 Raleigh Molecular Laboratories – All Rights Reserved.